The IoT Study Group, which is a business organization of the Japan Packaging Machinery Manufacturers Association, held a comprehensive exhibition on packaging processes "JAPAN PACK 2022" (real exhibition, February 15-18, 2022, Tokyo Big Sight) , showed a demo machine of "Quality AI Checker".

"Quality AI Checker" demo [click to enlarge]The IoT Study Group, which was launched in April 2019 under the IoT support project of the Tokyo Metropolitan Industrial Technology Research Center, At "JAPAN PACK 2019", we are exhibiting a panel titled "IoT Proposals to Solve Problems in the Packaging Industry". The quality AI checker exhibited this time is a proposal for solving quality improvement, technology transfer, and lack of human resources among the issues occurring at the production site presented at JAPAN PACK 2019. AI (artificial intelligence) and human sensitivity The concept is the fusion of

The quality AI checker demonstration machine is positioned as a system that inspects the baking condition with an AI camera as a pre-process for packaging cookie pillows. Defective cookies that pass through as non-defective products are inspected by experts, and AI learns the inspection results to perform better inspections.

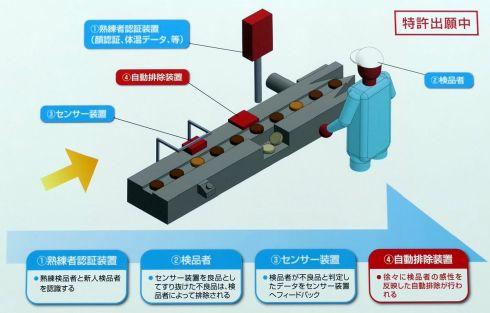

Concept of "Quality AI Checker" [Click to enlarge] Source: IoT Study GroupSystem consists of "expert authentication device", "sensor device", "automatic exclusion device", and 4 inspectors consists of one element. The "skilled person authentication device" recognizes skilled inspectors and inexperienced inspectors by facial recognition using a camera. In order to respond to the new coronavirus infection (COVID-19), face recognition is possible while wearing a mask, and body temperature data is also measured at the same time.

The inspector is authenticated by the "expert authentication device" (left). It is possible to confirm that the "expert authentication" of the inspector is being performed even on the HMI of the actual demo machine (right) [Click to enlarge]The "sensor device" determines how well the cookies are baked. It is a mechanism that feeds back the inspection results to the algorithm of the AI camera with an AI camera that performs inspection and passing sensors installed before and after the inspection process of skilled inspectors. The "automatic removal device" is a device that removes cookies that are judged to be defective by an AI camera out of the line.

Inspecting the baking condition of cookies with an AI camera with lighting (left). However, in the inspection of AI cameras with shallow learning, cookies with intermediate baking quality can slip through, but this is covered by inspection by experts. By learning this inspection result, the inspection accuracy of the AI camera improves (right) [click to enlarge]By repeatedly learning the inspection results of skilled inspectors, pillow packaging in the post-process waste can be reduced. "We would like to improve the accuracy of AI camera inspections by making it possible to learn not only the brown color but also the height and size of the product," said a staff member of the IoT Study Group.

AI camera inspecting the baking condition of cookies [click to enlarge]In addition, the IoT research group has applied for a patent on the quality AI checker.

⇒ Click here for other articles on "AI technology for manufacturing sites"